About

The Right Thermal Solution For You

Coil heaters are also referred to as cable heaters, hot runner nozzle heaters, spring heaters, hot sprue heater, or micro tubular heaters. Though often found in a spiraling or winding shape, a hot runner coil heater is not named after the shape of its exterior; the name refers to the resistance wire inside the heater that has a small winding pattern throughout the length of the heater.

Applications

- Plastic Injection Molding

A Nexthermal coil heater’s strength is its ability to be shaped specifically for your nozzle heating applications. The heat can be directed to specific sections of the nozzle by adjusting the winding tightness in different sections. - Mass Spectrometry

Nexthermal coil heaters are used in a broad range of scientific and medical applications. Small and light-weight coil heaters can be used to change liquid samples into vapor. - Food / Tray Seal Packaging

Our coil heaters generate heat evenly along the heater, perfect for creating even seals in any type of tray sealing application including non-standard shapes. - Rubber Injection Molding

Nexthermal can manufacture round coil heaters to be fitted into a plate used for rubber injection molding. In some cases, we have even designed the plate to gain optimal performance and energy efficiency from the heater, resulting in a longer heater life and faster throughput.

Nexthermal coil heaters

- Range from Micro, Mini to Maxi Coil heaters so you can choose the right size and wattage capability for your application

- Includes internal thermocouple options or may be used with external thermocouples

- May be wound to directly fit a nozzle, embedded in a thermal mass for nozzle, formed into a grove for three dimensional heating, or can work as an easy-to-remove cartridge heater alternative

- May be manufactured with longer cold sections to allow higher temperature applications to utilize flexible leads and moisture resistance

Coil Heater Profile Comparison

Ideally suited for pressed in groove applications, highly flexible heater with integrated thermocouple

High surface contact for good heat transfer to the tool. Can be used with a clamping strap or Constrictor

The benefit of good heat transfer and higher allowed watt density for higher temperatures

Highly adaptable small format heater that can be designed to provide good heat density as well as flexible design

Increases the heat energy reflected into the tool, increasing its efficiency by about 20%. Designed to slip fit the heater onto the tool.

Wind from Stock

2.5 mm x 3.4 mm (0.098″ x 0.134″) Flat Coil Heater (240V)

10.5

12.5

16

19

22

26

30

36

38

42

45

75.28

79

86.6

14.5

16.5

20

23

26

30

34

40

42

46

49

78.84

82.56

90.16

215

250

325

390

470

520

610

630

700

800

850

1050

1150

1300

SPECIFICATIONS

Available Diameters

Maxi

Profiles

Minimum Inside Diameter

0.79"

Voltage

Minimum Bending Radius

0.393"

Straight Heated Length

86.6"

Thermocouple Availability (Type J / Type K)

Internal, External

Material Options

SS321

Round

Profiles

Minimum Inside Diameter

0.472"

Voltage

Minimum Bending Radius

0.236"

Straight Heated Length

86.6"

Thermocouple Availability (Type J / Type K)

Internal, External

Material Options

SS321

Flat

Profiles

Minimum Inside Diameter

0.472"

Voltage

Minimum Bending Radius

0.236"

Straight Heated Length

86.6"

Thermocouple Availability (Type J / Type K)

Internal, External

Material Options

SS321

Square

Profiles

Minimum Inside Diameter

0.472"

Voltage

Minimum Bending Radius

0.236"

Straight Heated Length

86.6"

Thermocouple Availability (Type J / Type K)

Internal, External

Material Options

SS321

Micro Mini

Profiles

Minimum Inside Diameter

0.236"

Voltage

Minimum Bending Radius

0.118"

Straight Heated Length

112.2"

Thermocouple Availability (Type J / Type K)

External

Material Options

SS321 or Nickel

Mini Flat

Profiles

Minimum Inside Diameter

0.236"

Voltage

Minimum Bending Radius

0.118"

Straight Heated Length

112.2"

Thermocouple Availability (Type J / Type K)

External

Material Options

SS321 or Nickel

Mini Round

Profiles

Minimum Inside Diameter

0.236"

Voltage

Minimum Bending Radius

0.118"

Straight Heated Length

112.2"

Thermocouple Availability (Type J / Type K)

External

Material Options

SS321 or Nickel

Maxi

Profiles

Minimum Inside Diameter

20.0 mm

Voltage

Minimum Bending Radius

10.0 mm

Straight Heated Length

2500 mm

Thermocouple Availability (Type J / Type K)

Internal, External

Material Options

SS321

Round

Profiles

Minimum Inside Diameter

12.00 mm

Voltage

Minimum Bending Radius

6.0 mm

Straight Heated Length

2800 mm

Thermocouple Availability (Type J / Type K)

Internal, External

Material Options

SS321

Flat

Profiles

Minimum Inside Diameter

12.00 mm

Voltage

Minimum Bending Radius

6.0 mm

Straight Heated Length

2800 mm

Thermocouple Availability (Type J / Type K)

Internal, External

Material Options

SS321

Square

Profiles

Minimum Inside Diameter

12.00 mm

Voltage

Minimum Bending Radius

6.0 mm

Straight Heated Length

2800 mm

Thermocouple Availability (Type J / Type K)

Internal, External

Material Options

SS321

Micro Mini

Profiles

Minimum Inside Diameter

6.00 mm

Voltage

Minimum Bending Radius

3.0 mm

Straight Heated Length

2800 mm

Thermocouple Availability (Type J / Type K)

External

Material Options

SS321 or Nickel

Mini Flat

Profiles

Minimum Inside Diameter

6.00 mm

Voltage

Minimum Bending Radius

3.0 mm

Straight Heated Length

2800 mm

Thermocouple Availability (Type J / Type K)

External

Material Options

SS321 or Nickel

Mini Round

Profiles

Minimum Inside Diameter

6.00 mm

Voltage

Minimum Bending Radius

3.0 mm

Straight Heated Length

2800 mm

Thermocouple Availability (Type J / Type K)

External

Material Options

SS321 or Nickel

Lead Protection

Fiberglass Sleeving

Fiberglass Sleeving

Braided Metal Sleeving

Braided Metal Sleeving

Flexible Armor Cable

Flexible Armor Cable

exit options

constrictor

Precise. Durable. Versatile. Nexthermal Coil Heaters deliver the performance you need for plastic injection molding, mass spectrometry, top seal packaging, food production, and your next innovation.

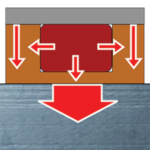

The Constrictor optional accessory is a retaining system that expands and slides over the open coil heater after the heater has been installed on a tool, holding tension on the heater during operation. The advantage of this accessory is it counters the natural expansion of the coil heater during thermal expansion. By doing so the customer can have several advantages

- Faster recovery time for the tool from better heat transfer

- Better temperature feedback to the thermocouple (if internal TC is used)

- Lower heat loss to the environment as the alloy has a high degree of thermal reflectivity back into the tool, which improves the energy efficiency

Available in a wide range of standard diameters, and available in standard length of 30mm to allow for positioning on the tool. In cases where the tool being heated is longer than 60mm, we have found its best used at the end zones of the tool and leave the center open, which reduces the heat buildup in the center of the tool and can thermally damage the tool or product being processed.

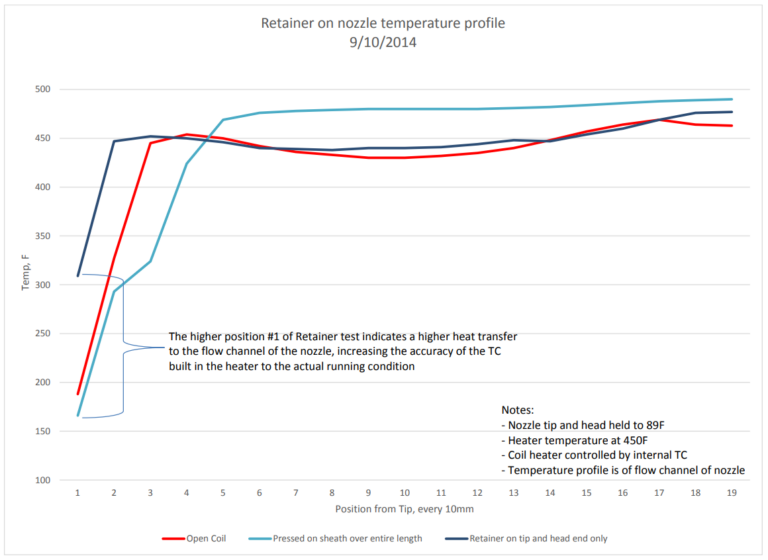

In the following graph testing a hot runner nozzle the dark blue line represents the performance difference using the Constrictor over the standard open coil (red line) and another option we offer of a Pressed On Sheath (light blue). In the test the tool had a Constrictor placed on the first 30mm and the final 30mm, leaving the center open coil. The Constrictor allowed for higher tip temperatures, better thermocouple accuracy and better manifold temperature – while allowing the plastic to be protected from heat related damage between molding cycles in the center of the nozzle.

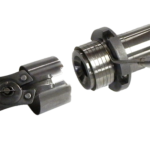

The Constrictor can be installed using our hand tool, or by a standard snap ring plier as well if available to the installer and care is taken not to over expand during installation which can distort the spring tension that it’s sized to hold.